When a fire broke out in an industrial plant in British Columbia, Newtron Group was called to inspect the damage.

A Project Manager was flown to Vancouver to conduct an on-site assessment of the equipment, which had been affected by both fire and water. The insured in this claim operated a business providing technology products to the photography and printing industries.

The area affected by the loss was the research and development department located in the lower level of their building, consisting of various research labs and engineering offices.

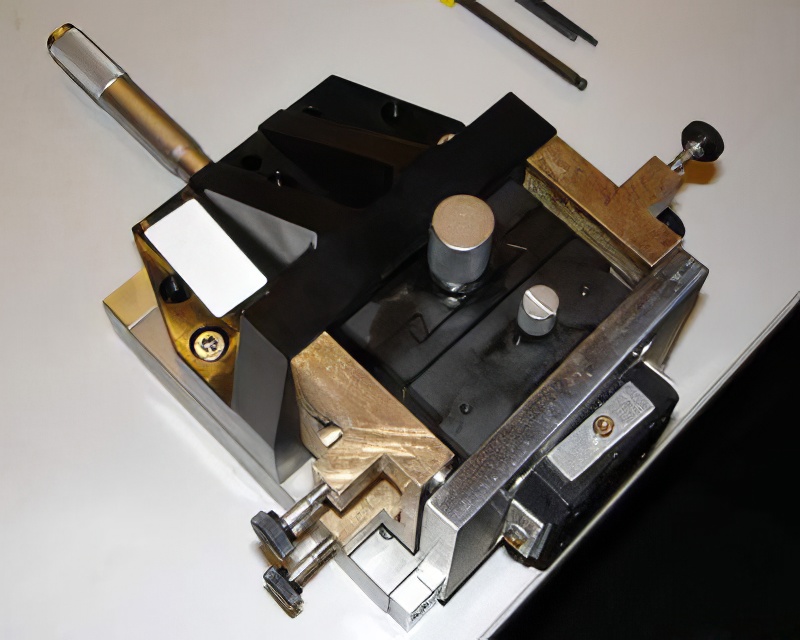

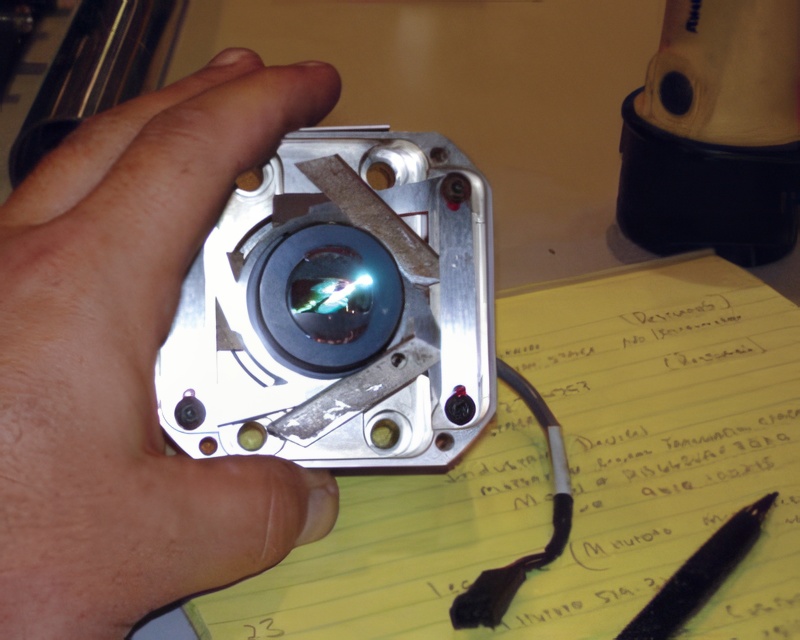

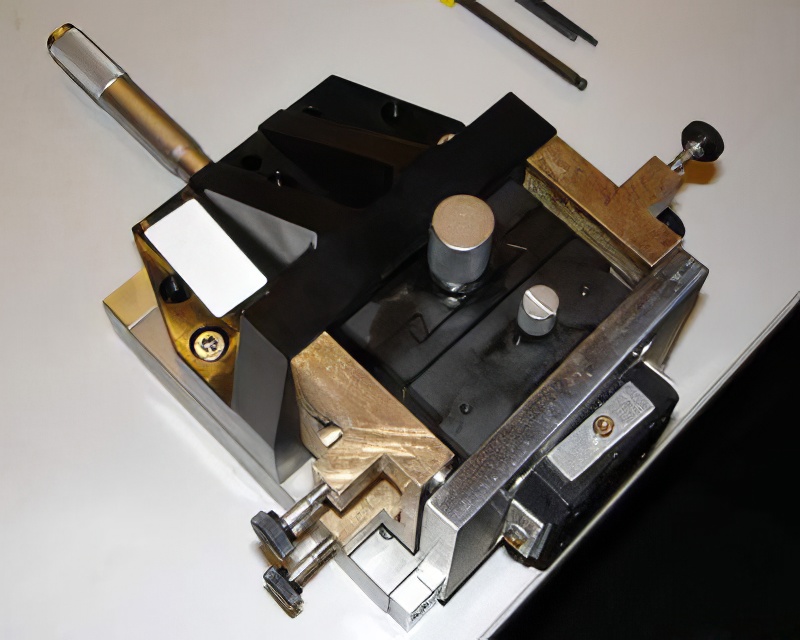

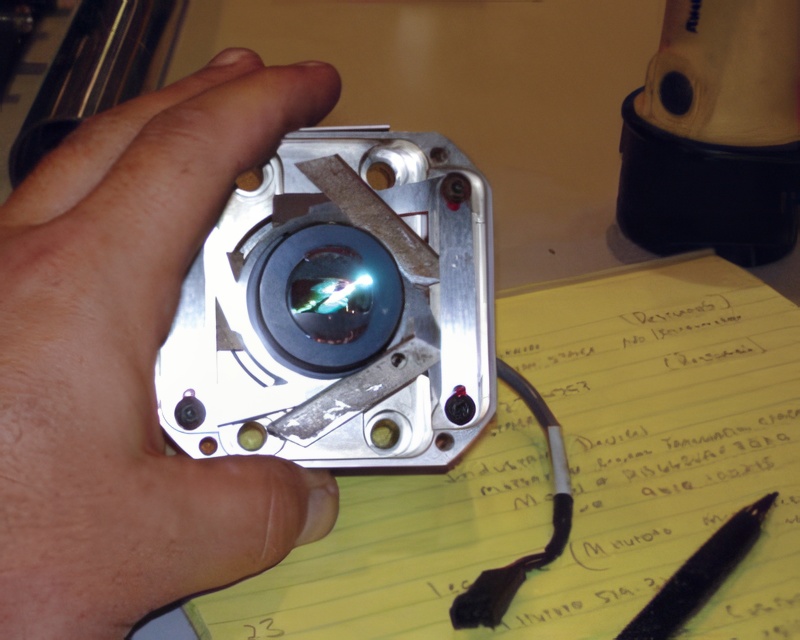

The majority of the equipment inspected was located in the lab where the fire originated and the surrounding labs. The types of equipment located in these labs were various mechanical and electronic pieces used in opto laser experiments, including numerous linear translation stages. The other area inspected included the engineering offices, which contained computers and other equipment that was located on the floor and exposed to water used to extinguish the fire. A Zyco Interpherometer was also inspected.

After the inspection Newtron Group supplied the insurance company with a thorough report on the status of the affected equipment. Some of the items, especially those located in the lab where the fire had originated, were found to have extensive smoke and water contamination.

At the time of the inspection irreversible corrosion had already occurred on this equipment. These items were deemed to be write offs because they were not restorable. Newtron Group then submitted a report of approximate replacement costs for all of these items.

Much of the other equipment, which did not come into as close contact with the heat and smoke of the fire, was in fact restorable. Newtron Group recommended that all the affected restorable equipment be subject to a thorough decontamination to prevent any further deterioration and to prevent the potential of high cost repairs and/or replacements in the future.

Once Newtron Group received approval several technicians were flown over to Vancouver to begin emergency on-site decontamination. Following the thorough cleaning of the restorable items Newtron Group collaborated with the vendors selected by the insured to complete full functional testing and to ensure final certification of the equipment.