Newtron Group was called in when a food packaging plant was hit by fire, which caused smoke damage to the office area and the warehouse. The insured marketed dry fruit and nut products to the food retail industry, and their production process included the packaging of their goods.

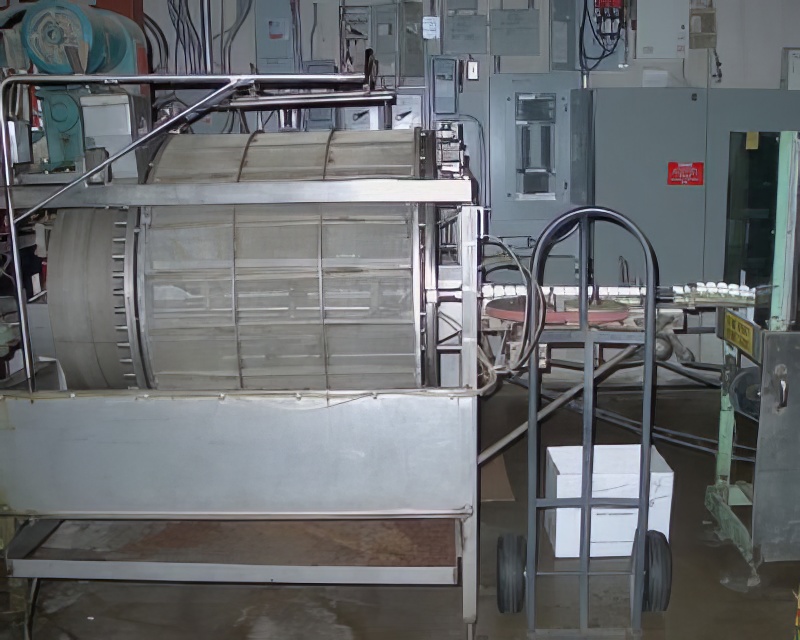

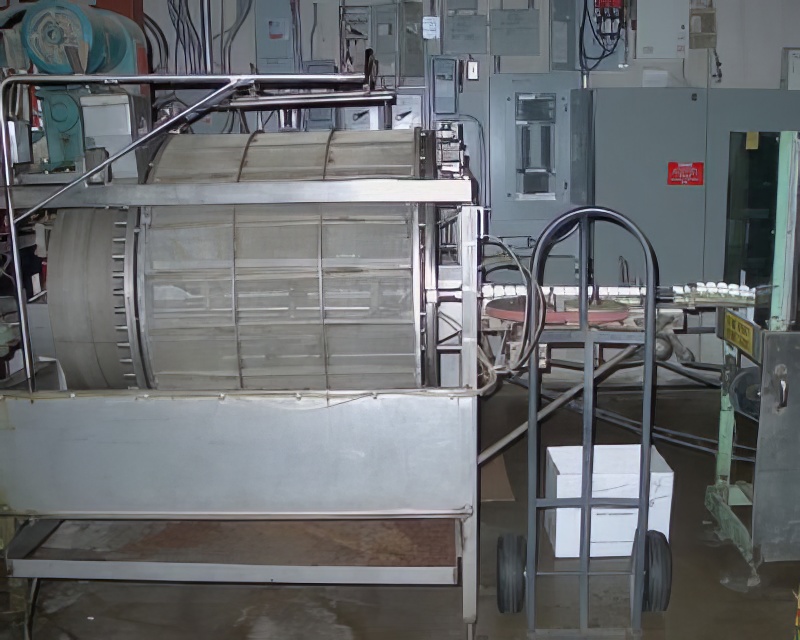

The warehouse in the plant contained several pieces of machinery including product packaging and roasting equipment. Due to the fact that most of the production line machinery were not enclosed units many of the internal machinery components were exposed to light smoke contamination. These machines all handled the pre-packaged food and at the time of Newtron Group’s inspection some still contained food products and the roasters contained grease that had been contaminated by the smoke.

Newtron Group put all of the equipment through a thorough decontamination process to prevent further damage from occurring and to prevent any future food products from being contaminated by the machinery as a result of the fire. Newtron disassembled, decontaminated and then reassembled the equipment and also removed the food product. In addition to using the traditional decontamination process Newtron Group also implemented some dry ice blasting methods.

Newtron Group was able to act quickly and efficiently, assessing the situation in a timely manner and beginning emergency restoration almost immediately, in order to accommodate the insured and get their production back on track as quickly as possible.