Newtron Group was called in to inspect a plastic injection moulding plant after a water main broke and flooded the facilities.

The broken water main caused water, mud and silt to enter the building, covering the entire ground floor area. The first floor of the plant consisted of the production area, quality control room, maintenance rooms and offices. During an emergency on-site inspection Newtron Group’s Project Manager noted that the water level varied throughout the affected area up to a couple of inches.

The equipment inspected was located throughout a number of areas on the ground floor. The majority of the equipment was located in the production area, which contained forty-four plastic injection moulding machines of various makes and sizes. The moulds that were used in the machines were located in the northeast corner of the production area.

These moulds were used to create the end product from the machines. The maintenance department consisted of three rooms that included the tool room, grinding room and the EDM room. The type of equipment found in these rooms included a CNC machine, various drilling/milling machines, EDM machines and various bench tools used in the maintenance of the equipment and moulds.

Also located in the maintenance area was the main electrical transformer room for the entire building. Located towards the front of the building was a Co-Ordinate Measuring Machine. This unit was used for quality control measuring of up to one hundred thousandth of an inch and is sensitive to varying degrees in temperature and humidity. Also inspected were a number of computers and associated equipment that were located throughout the plant, including the quality control and scheduling offices.

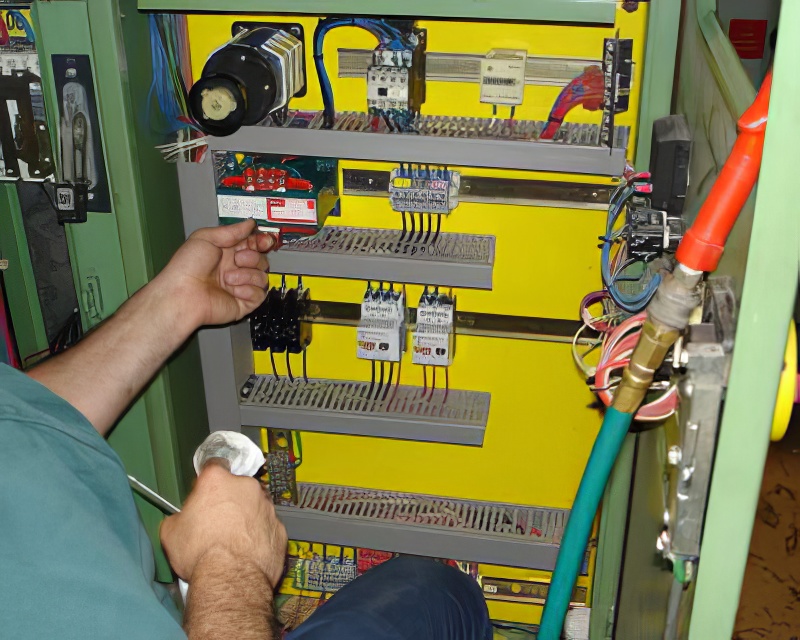

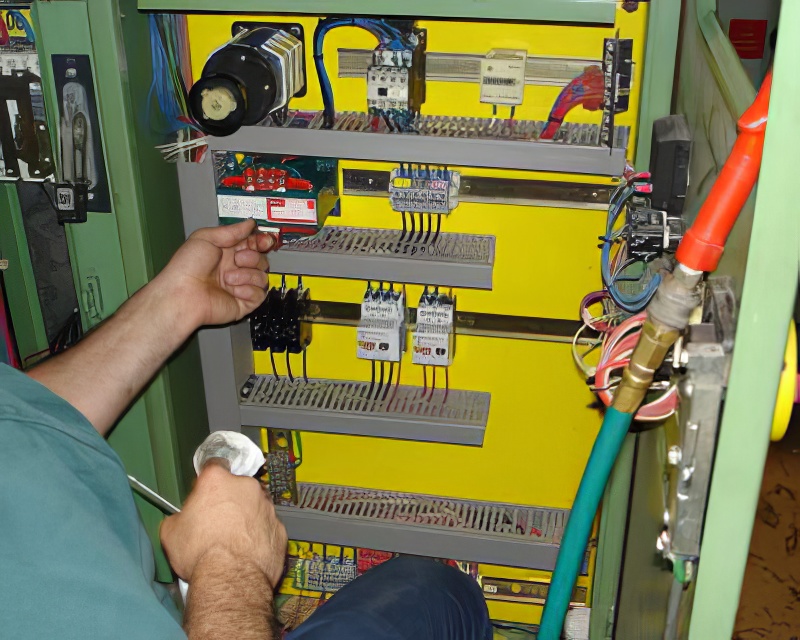

After inspecting the premises and meeting with the insured Newtron Group was able to report to the insurance company regarding the extent of damage to the affected equipment. Newtron Group was also able to convey that the insured’s main concern was the electrical/electronic controls of the production equipment, which were located closest to the floor. Our inspection verified these concerns and in the report we recommended that all the controls and electrical distribution panels closest to the floor be fully decontaminated to prevent any further deterioration from occurring.

Newtron Group also observed standing water and silt in a number of 600V distribution panels located at the input side of the machines in question as well as in another machine in our inventory. Also, it was reported that inspection of the LK CMM indicated water damage throughout the bottom of the LK 4000 controller, the control CPU and the base of the CMM itself. Flash corrosion was observed on the bottom feet of the platform containing the granite base and this was identified by the insured as a priority item.

A number of PCs and associated computer equipment that were located on the floor in the quality control, scheduling, production, and human resources offices-some of which were identified as priority items-were also reported as directly being affected by water and silt. The IT department provided Newtron with a number of power bars, keyboards, mice and speakers that were directly affected by the loss and had been removed by them. Also, Newtron discovered that there were several pieces of computer equipment that had been submerged in water and that required replacement.

Newtron Group reported that, in our opinion, there were no concerns in regards to the affects of humidity on the equipment as the company operates production in a non- temperature controlled area and the machines were designed to withstand some degree of temperature and humidity change. For example, the machines have a constant flow of coolant and hydraulic oils that runs through them during normal operation, which would have continued to work after the loss, and saved the machines from exposure to corrosion caused by humidity.

Also, the inspection of the transformer room indicated silt and water had entered the room but made no direct contact with the equipment because all the electronics were high off the floor. The insured’s electrical contractor who commented that there was no direct damage and that everything in the room was working properly confirmed Newtron’s assessment that none of the transformer room equipment had been directly affected by the loss.

Following the inspection and report submission Newtron Group received permission to go ahead and restore the affected equipment on an emergency basis. Newtron Group commenced decontamination of all the electrical/electronic controls in all of the plastic injection moulding machines located throughout the production area, thirteen of which were identified as priority.

The LK CMM machine and associated equipment were also identified as priority and cleaned as quickly as possible. The controllers, and office and computer equipment were also restored on an as-required basis. Thus, Newtron Group was able to identify the equipment that required restoration and was able to decontaminate these items in a timely fashion, as indicated by the insurance company and required by the insured.